Product Prototyping Services

Prototyping

We believe you can't prototype enough. Whether through quick validation models to prove a theory of function early in the development process, or fully functional "looks like - feels like" prototypes for functional or marketing testing, we have the resources to bring a design to life.

Knowing what and when to prototype saves you money and time. The design process heavily relies on physical product prototype work to deliver successful product design solutions.

There are a variety of different tools and processes we use within this stage to build prototypes. Every project has its own goals and requirements – we provide prototype development services to help provide value by recommending which tools and processes are an appropriate fit to meet the needs of your project.

DESIGN VALIDATION MODELS

Validation models provide a pragmatic means to assess the viability of conceptual designs and innovative ideas. These prototype development models are created quickly with straightforward means, serving the singular purpose of determining whether a particular concept merits further development. These models do not include details such as material, color, or finish, and sometimes they don't reflect size or scale.

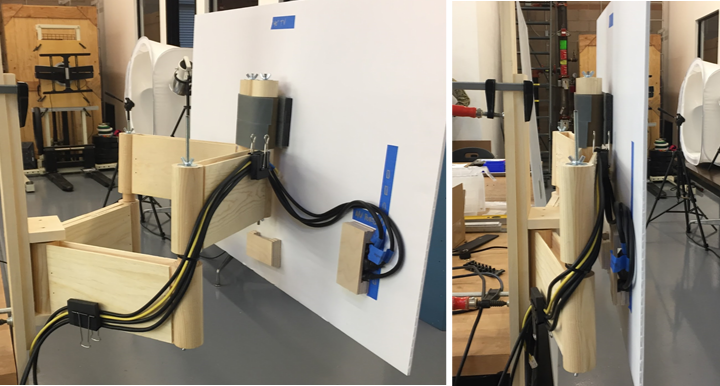

In instances where the concept involves functionality, more sophisticated approaches may be employed, such as kit-bashing existing products to replicate the intended functions within the specific context of the concept. This dynamic approach, combined with product prototyping services, allows for a focused evaluation of key design elements, ensuring that the concept aligns with intended goals before progressing to more intricate phases of development.

PROOF OF CONCEPT (POC)

Throughout development, there will be the need to test the feasibility, functionality, and viability of a concept or product idea. This is what proof of concept (POC) models are for, and should be completed as often as needed to guide the direction of the project before significant resources are invested. Innovative products are the result of testing a design concept over and over before it can become a successful final product. A new product idea or technology goes through a complex process of iteration to validate its functionality and viability.

Often completed at the earlier stages, POC models either confirm to push for further development or serve as a basis for further iteration. Rapid prototyping and iteration are key here. These models are created quickly, allowing for adjustments or pivots based on the results. If risks or challenges are identified, this gives time early on to address technical, operational, or feasibility issues in the project.

APPEARANCE MODELS

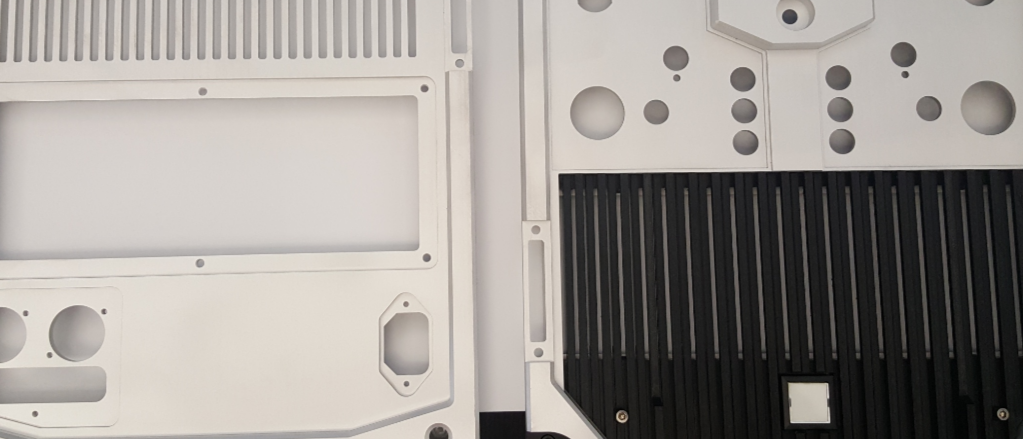

Appearance models serve as representations that support size, color, finish, and, in many instances, materials. This provides a model that "looks and feels like" a manufactured product, but doesn't require the actual manufacturing process that would be used for final production parts.

An appearance model is typically the next step after renders and CFM efforts, and is a rapid prototyping effort to better understand product features. The goal is to create a quick turnaround model that can be reviewed and evaluated by stakeholders, user focus groups, and potential investors for further project funding.

These prototypes often incorporate a degree of functionality to authentically convey the envisioned appearance, such as a working display to represent an application or functional buttons to simulate tactile feedback. Notably, there is a growing trend to opt for an advanced digital approach to storytelling the design solution using renders and animations. But in just about every scenario, clients love to see and touch a new creation!

VERIFICATION PROTOTYPE / IN-FIELD EVALUATION

Functional prototypes serve as models that effectively convey both functionality and aesthetic appeal. In many instances, these prototypes are the most efficient and valuable in the prototyping process. Beyond their suitability for end users, these prototypes play a crucial role in the sign-off process involving assemblers, service teams, and technicians. To ready a product for mass production, verification prototypes are often the last step to approve a product design before full scale manufacturing begins.

Our product development services in prototyping, tailored to each prototype's specific use and objectives, encompass a range of processes such as CNC machining, 3D printing, casting, and forming techniques. But know your customers, and don't assume during user testing/evaluation sessions that they will regard the prototype the same as you! Users will often handle and utilize a specific product differently than the designers and engineers who developed it.

FAQ’s

-

This question is asked often, and it is really difficult to pinpoint an answer because there are so many variables, from product complexity, testing, user/focus group feedback, certifications, etc. In a perfect world, we recommend our clients allocate up to 8-15 weeks, depending on the complexity and the speed at which client feedback.

2-3 weeks for research/strategy,

3-4 weeks for concept development,

3-5 weeks for mechanical development/implementation,

3-4 weeks for prototyping.

In most cases, this doesn’t mean you are ready for tooling!

We will gladly share a case study of our process and work - walk through a timeline from start to finish to give you a more realistic timeline for your project.

-

In many cases, especially larger corporations producing products an in-house creative team exists. One of our strengths is the ability to adapt and challenge the status quo without compromising the creative value you need.

-

This question comes up frequently, and giving an exact estimate can be challenging due to the presence of several variables. Nevertheless, in many cases, we segment project estimates into distinct phases to ensure transparency and clarity in assessing the required effort.

-

Radiant gives support for the full-scale product development process. Although we are not a manufacturing company or exclusive prototyping firm, our goal is to provide a full spectrum of services through both our in-house team as well as our local and international partners. To provide the best development, we handle product prototype design work in-house and through the quickest means to validate and iterate. Manufacturing and production are the expertise of our partners, and we do our best to provide options that can fit your plans and business model.

-

Yes. We understand the hurdles and complexities that come with launching a new startup or building a brand — it's no small feat. Recognizing the various challenges, we, as partners, are prepared to contribute our design services as a form of capital tailored to the specific needs of the venture.

-

This varies. Our standard payment terms are net 15 days. We offer flexibility to our long-standing clients and established relationships, allowing for a net payment period of 30 days or more.

-

At the beginning of any project, many preconceived ideas won't materialize or reach fruition. And the problem-solving process in new product development is rarely linear. Our objective with any client project is to offer transparency throughout the process, including risks and opportunities. We have a clear goal of providing you a solution that meets your business objectives and delivers a product your customers will love.