Design and Engineering Consultants for Hardware Companies Ready to Scale

We Don't Just Execute - We Identify, Challenge, and Optimize

Why Radiant?

Most Firms Sell You More Hands.

We Sell You Better Thinking.

The Capacity Trap

Think you need more designers? You might not! Your challenge isn't lacking talent, it's strategizing new ways to scale without adding headcount.

The Blind Spot Problem

Internal teams miss opportunities and risks that become invisible when they’re deep in the work. Time pressure, corporate routines, and proximity create natural blind spots needing an external perspective to identify.

The Radiant Difference

We embed as strategic partners who identify blind spots, challenge assumptions, and optimize processes, making your team faster on future development.

How We Multiply Capabilities

01. We IDENTIFY what proximity obscures

External perspective catches opportunities, assumptions, and constraints that internal teams can't see. We ask questions that haven't been asked and identify what's actually slowing you down.

Early in Rockford Fosgate's NPD process, their team saw two speaker variants requiring two separate grilles. We saw one design solution that could create both options.

The result? Patent D931833—a single grille design that eliminated the need for separate tooling while delivering two distinct product variants.

01. Identify

02. Challenge

03. Optimize

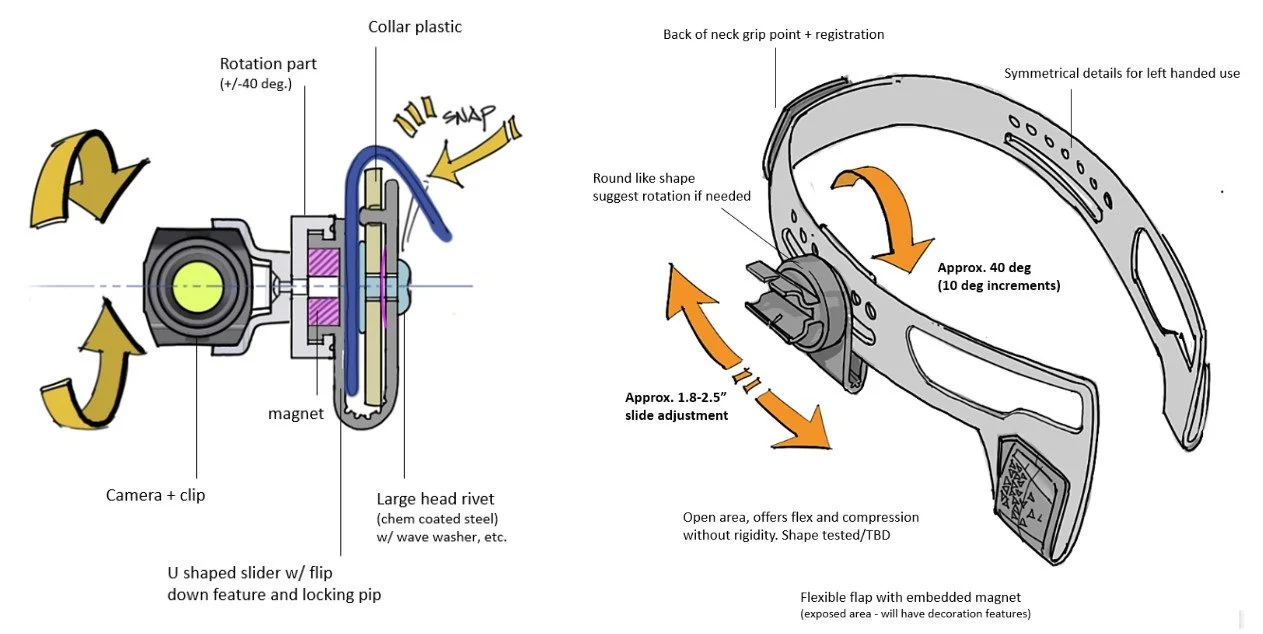

02. We CHALLENGE assumptions before validating them

We challenge constraints that slow progress without providing value - and test assumptions before committing to expensive tooling or production decisions.

For VeriFAST, questioning one camera requirement unlocked a simpler, better solution.

03. We OPTIMIZE through Convergent Design

Our approach brings disciplines together from day one. Engineers and designers co-create from concept, not handoff. Manufacturing constraints inform creativity instead of restricting it. Teams prototype with production intent from sprint one, eliminating the expensive back-and-forth that happens when design "throws it over the wall" to engineering. For Havis we were able to…

16 parts → 9 parts. 40%+ cost savings. Months saved.

That's what happens when engineers and designers work together from day one instead of in sequence.

Convergent Design eliminates the expensive back-and-forth.

Capabilities

We don't offer pre packaged services. We bring together the strategic and technical disciplines you need, customized to your unique challenges.

Most firms specialize in either design or engineering. We integrate both from day one through our Convergent Design approach, eliminating costly handoffs and accelerating time to market. Every engagement is different because every company's situation is unique. We combine the capabilities below based on where external perspective can multiply your team's effectiveness.

Industrial Design

Beautiful designs that can't be manufactured aren't designs, they're expensive mistakes. We integrate aesthetics with production realities from concept, catching manufacturability issues before they become expensive problems.

Product Aesthetics

Human Factors and Ergonomics

Design Validation Models

Conceptual BOM

CAD development

Color, Finish, Materials (CFM)

Prototyping

Assumptions are expensive, while prototypes are cheaper. You can never have too many prototypes. We build physical models to test fit, function, and user interaction before committing to tooling, catching problems when they're easy to fix, not after you've cut steel.

Proof-of-Concept Models

Functional Prototypes

Iterative Refinement

Form & Fit Validation

User Testing Models

Pre-Production Samples

Brand Development

Your brand isn't your logo, it's the promise your product makes and whether it delivers. For professional hardware, branding isn't about looking cool. It's about building trust with users who depend on your equipment to do their jobs well, day after day.

Brand Strategy & Positioning

Visual Identity Systems

Product Graphics & Badging

Packaging Design

Marketing Collateral

Brand Guidelines & Standards

Product Visualization

Renderings aren't just pretty pictures, they're decision making tools. High quality visualization helps teams align on direction before expensive commitments, secures stakeholder buy-in, and communicates intent when CAD alone won't convince.

Product Renderings

Exploded Views & Technical Illustrations

Animation & Motion Graphics

Lifestyle & Context Imagery

Marketing & Sales Collateral

Funding Presentation Materials

Mechanical Engineering

Engineering that works on paper but fails in production isn't engineering, it's expensive theory. We validate designs through analysis, prototyping, and manufacturing collaboration before tooling commits, so products perform in the real world - not just in CAD.

Engineering Validation

Development & Detail Design

CAD Development & Modeling

Design for Manufacturing (DFM)

Tolerance Stack - Up Analysis

Material Selection & Specification

Prototyping & Testing

Documentation

Manufacturing Support

We don't just hand off CAD files and hope for the best. We collaborate with manufacturers through DFM reviews, vendor selection, first article inspection, and production ramp, building manufacturing partnerships that make future projects faster, not just getting this one part made.

Design for Manufacturing (DFM) Reviews

Vendor Selection & Qualification

First Article Inspection (FAI)

Tooling Review & Optimization

Production Ramp Support

Quality & Process Troubleshooting

Design Strategy

Strategy isn't a deck, it's problem solving through the right questions. We help teams step back and ask: Is this the right problem? Does this approach serve the goal or just feel familiar? What assumptions are we validating versus blindly accepting? Strategy aligns user needs with business objectives. Every solution has a story, we help you find the one worth telling.

Strategic Planning & Direction

Market & Competitive Research

User Research & Pain Point Analysis

Opportunity and Risk Identification

Concept Validation

Product Requirements Definition (PRD)

Built For Hardware Companies Who Are Ready To Scale

Are you a good fit?

We work best with hardware companies at a specific growth stage: you've proven product-market fit, you're scaling your portfolio, and you need strategic perspective more than additional headcount.

If your challenge is multiplying capabilities without multiplying team size, we're built for you.

You're scaling product operations

You have an active product development roadmap

You value strategic thinking over cheap labor

Your team is strong but needs external perspective

You're ready to invest in capability, not just capacity

Who we work with

Professional Hardware Where Design Quality Matters Every Day

We focus on hardware where design decisions have business consequences - and where users depend on their equipment to do their jobs well, day after day.

First responders in critical moments. Technicians operating point-of-sale systems. Scientific professionals conducting research. Audio engineers perfecting sound. IoT users managing connected systems.

Good design doesn't just improve business metrics - it changes how people feel about their work. When hardware works intuitively and performs reliably, users go home feeling like they accomplished good work. When it fights them, even productive days feel draining.

Our cross-industry experience means we understand what makes professional hardware truly work: it supports the job to be done, eliminates friction, and lets users focus on their expertise instead of fighting their tools.